what kind of junction box do i need to run power into a shed

Electrical Wiring: How to Run Electrical Wire Outside

The easiest fashion to bring electricity to a shed, garden or lamppost

![]() Time

Time

A total day

![]() Complexity

Complexity

Intermediate

![]() Cost

Cost

$101–250

Introduction

Learn how to run electrical wires outside underground to accomplish sheds, lights, patios and other locations, following safety wiring practices.

Tools Required

Materials Required

- Duct seal

- Electrical boxes

- Electrical tape

- EMT (electrical metallic tubing)

- Fish tape

- Fittings (connectors and LBs)

- GFCI

- Leather gloves

- Mattock

- Piping bender

- RMC (rigid metallic conduit)

- Stranded electrical wires

- Switch

- Two (white and black) conduit straps

- Wire connectors

Overview: Projection Scope, Special Tools, Materials and Costs

Dragging extension cords across the yard to ability the string trimmer, fumbling effectually in a dark shed…nigh of united states take these hassles for granted. Only information technology doesn't have to be that style. With a day'south work, y'all tin run electrical lines to whatever function of your grand.

This article volition prove you lot how to bring power to a shed, only the process is almost identical if you want to simply mount an outlet on a postal service planted in the soil.

A licensed electrician would charge at least several hundred dollars plus materials to run lines from your house to a shed 50 feet abroad (not including whatever work inside your house).

Running Power Through RMC

Nosotros'll show you lot how to run wires through rigid metal conduit (RMC). This method offers the best protection of the wiring and requires the least corporeality of digging. It likewise lets you install a GFCI outlet at the end of the line rather than at the house, which means you lot'll never accept to run back to the house to reset a tripped GFCI.

If you lot want to provide a dedicated circuit to the shed, rent an electrician to make the terminal connectedness in your main electrical panel. Otherwise you can connect to an existing circuit if the circuit has enough capacity and the box you're connecting to has plenty volume for the additional wires.

Running Wires Within Rigid Conduit

To run the wires within rigid conduit, you'll need a hacksaw, a pipe bender capable of angle 1/ii-in. rigid conduit with an outside diameter of 3/4-in., and a fish tape long enough to reach through the buried pipage.

You'll also need a pair of piping wrenches to screw the sections of pipe together, a drill and one-inch bit capable of penetrating your siding, and wire cut and stripping tools.

A few weeks before you get-go the project, contact your local building section to obtain an electrical permit if ane is required. Then a few days earlier y'all dig, call 811 to take your underground utility lines marked. Learn more at call811.com.

Projection footstep-by-footstep (12)

Step i

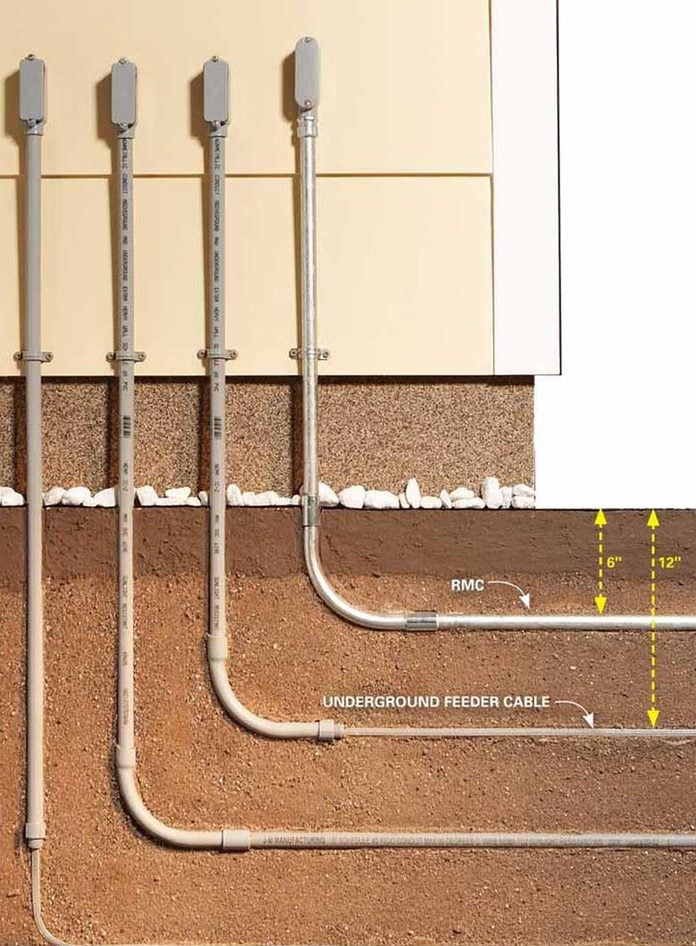

Using Metallic Conduit Means Less Excavation

- Running wires inside rigid metal conduit (RMC) is a little more expensive than burying surreptitious feeder cablevision (UF), merely information technology saves labor.

- This is because the superlative border of RMC has to be simply six inches below the surface of the ground, while UF must be buried 12 inches deep (deeper in some situations).

- That actress vi inches of trench depth may not seem similar a big deal. But information technology adds hours of arduous work, especially if you have rocky soil, hard dirt or lots of tree roots.

Footstep 2

Plan the Conduit Route and Dig the Trench

- Utilise a mattock to dig the trench. The narrow head means less dirt to remove and less to put back.

- Slice out strips of sod with a spade so you tin neatly patch the lawn later.

- In that location are several factors to consider in planning the route from the firm to the shed.

- Apparently the shorter the trench, the less digging yous'll take to do. Simply you lot besides accept to make up one's mind where you lot're going to connect to power inside the house and how easy information technology will be to go at that place.

- In some cases, a footling more digging could save you from having to tear into a basement ceiling.

- Get-go by locating a ability source, whether it's your main console, a ceiling box, outlet or other electrical box.

- Then figure out the best spot for the new conduit to enter the firm.

- Pro tip: Since the National Electric Code (NEC) limits the number of bends y'all can make in the piping to a full of 360 degrees, you lot have to plan the road advisedly. The 2 90-degree bends from the ground into the business firm and shed eat 180 degrees, leaving you 180 degrees more than for any additional bends.

- With the route planned, you can mensurate for the corporeality of wire and conduit you need and head to the hardware store or dwelling house centre.

- Add x feet to the length of wire and pipage to make sure you'll have enough.

- It's smart to drill the hole into the business firm before you kickoff excavation only in case you see an obstacle and take to choose a new location.

- When you're sure of the exit point, dig a trench from the house to the shed.

- Pro tip: If you're going across a lawn, remove a slice of sod the width of a spade from the surface and set it aside to reuse subsequently you bury the pipe.

- Then use a mattock or narrow spade to dig the trench.

- Pile the dirt on plastic tarps and then you don't have to rake it out of the grass after.

Stride 3

Mount the LBs and Metal Boxes

- The rigid conduit will come out of the ground and into a fitting called an "LB."

- The LB has a removable cover that simplifies the task of pulling wire by eliminating a sharp right-angle plough.

- The trickiest part of this project is mounting the LBs and connecting them to metallic boxes inside the business firm and shed.

- In general, you lot'll have to choose a box location and so summate the length of electrical metal tubing (EMT) needed to reach from the back of the LB to the box.

- Pro tip: If you're going into a basement or crawl space, the length of the conduit usually isn't critical.

- Offset by drilling a pocket-size pigsty with a long bit to make certain you lot're in the correct spot.

- And so drill a one-inch hole for the LB and conduit.

- Spiral a i/two-in. conduit connector into the dorsum of the LB and and so attach a piece of 1/2-in. EMT that'south long enough to reach an hands accessible box in the basement or crawl space.

- After you lot've mounted the LB to the siding, become inside and add a conduit connector and a metal electrical box to the other end of the EMT.

- This box is where you'll make the connections from your house wiring to the new shed wiring.

- On the inside of the shed, you'll screw a 4 ten iv-in. foursquare metallic box to the side of the stud.

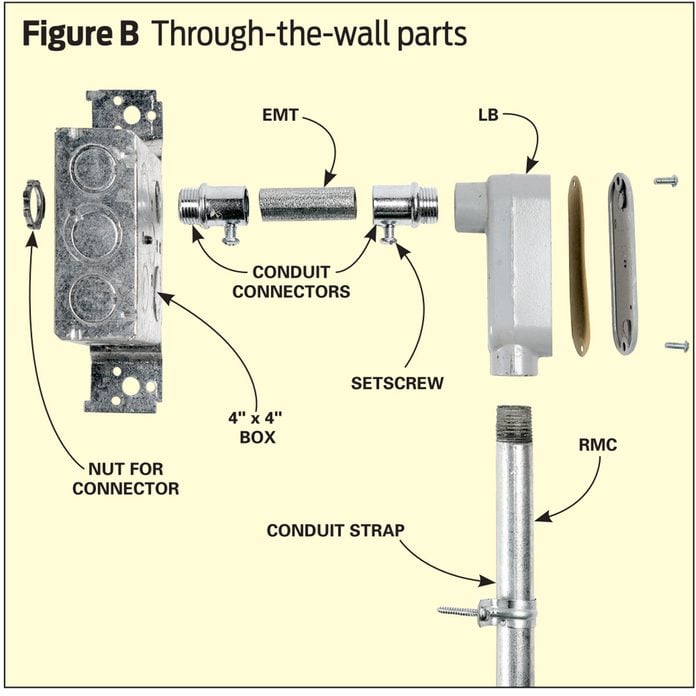

- Then connect the LB to the box using the parts shown in Figure B (below).

Pace four

Figure B: Through-the-Wall Parts

- Running the conduit through the wall to an inside box is the most hard step.

- The 10-human foot lengths of RMC are threaded on both ends and include a coupling on i end.

- You'll kickoff by bending the first pipage and threading an LB onto the end.

- So thread the pipes together one at a time until you lot reach the other end, where you'll cut and bend the terminal piece of conduit to fit and connect it to the LB with a compression connector. The photos beneath show the procedure.

Step 5

Run the Metal Conduit and Plan the Bend

- Temporarily attach the LB to the shed and mensurate from the bottom of the trench to the bottom of the LB fitting.

- Add together 3/4-in. for the threads that'll go into the LB and subtract the bending assart listed on your bender (unremarkably half-dozen inches) from this measurement for the bend.

- Marking this length on a piece of conduit, measuring from the cease with bare threads.

Step 6

Bend the Conduit

- Pull back on the conduit bender until the end stands direct up.

- A magnetic level lets y'all know when you've got a perfect 90-caste bend.

- Take the bent conduit back to the trench and screw the LB onto the end.

- Align the mark on the conduit with the pointer on the bough.

Step vii

Join the Conduit

- Assemble the conduit run aboveground to make tightening the connections easier.

- Support the conduit with 2x4s until you lot've continued all but the last section.

- Connect lengths of conduit until you reach the business firm.

Step eight

Plan the Final Slice

- Bend the concluding piece of conduit up and cut it off to fit into the compression connector.

- Offset past measuring from the last piece of conduit to the house wall.

- If the LB is held away from the wall by siding, decrease this distance from the measurement.

- And so add 3/4-in. for the threading and subtract for the bend.

- Arrange the measurement for the distance the LB protrudes from the wall.

- Mark the final piece of conduit, starting from the blank threads.

Step ix

Marking and Cutting

- Agree the bent conduit in place to mark it for cut starting from the comport threads.

- Since in that location are no threads on the terminate of the pipage, screw a compression fitting into the LB and connect the conduit to information technology.

- Face up the threaded end of the conduit when you make this bend, non the end with the coupling.

- Mark the conduit and cutting information technology with a hacksaw.

- Remove burrs from the within of the pipe by smoothing with a file or by inserting the bare metal handles of pliers into the pipe and twisting.

- Complete the conduit run past threading on the last piece of conduit.

- You'll have to lift the previous slice of conduit to create clearance every bit yous spin the bent pipe around.

- Finally, slip the end of the conduit into the compression connector and tighten the compression nut with a wrench.

- Wrap a conduit strap around the conduit and screw it to the house to secure the conduit.

- Also press a rope of "duct seal" around the top of the LB to keep h2o out.

Stride 10

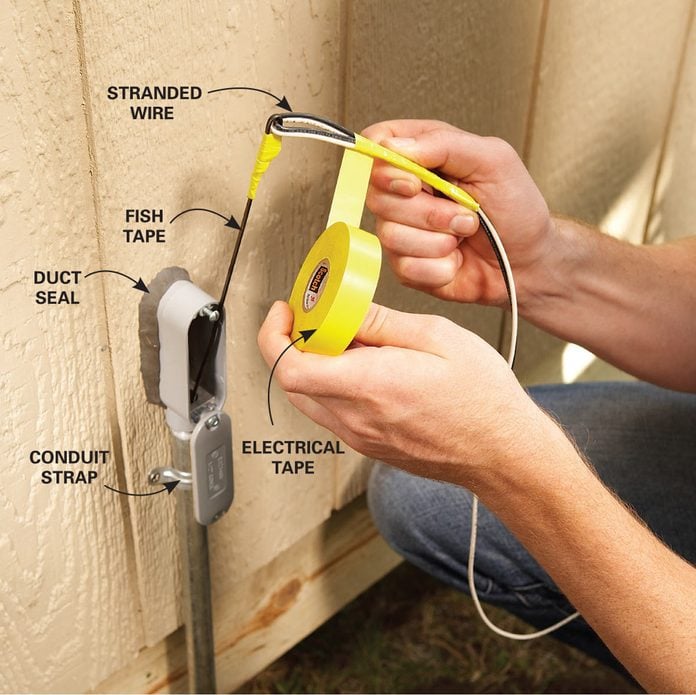

Tie the Wire to Fish Tape

- Remove the covers from the LBs and button a fish record through the conduit.

- Feed the fish tape through the conduit.

- Loop the wires through the fish tape and wrap them with electric tape.

- Likewise wrap the hook on the fish tape and so it tin't snag.

- Employ stranded wire, non solid wire.

Step eleven

Pull the Wires

- Pull the wires through the conduit.

- Pro tip: This is a two-person job — yous demand a helper at the other finish to feed the wires into the conduit.

- You'll need two wires, one white and 1 blackness, for one circuit, or more if you lot intend to wire a 3-manner switch from the house or add together more than one circuit.

- Use THWN-two, 14-gauge stranded wire if y'all get ability from a 15-amp circuit, or THWN-2, 12-gauge stranded wire for a 20-amp excursion.

- Leave enough actress wire on each finish to attain the inside metal box plus 12 inches.

Step 12

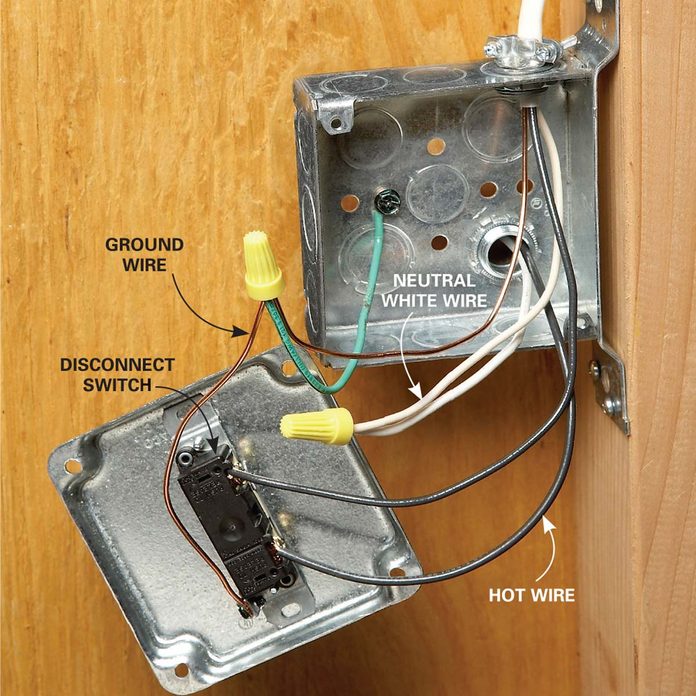

Showtime with a Switch

- The NEC requires a ways, such as a single-pole switch, to disconnect the power where it enters the shed.

- Pro tip: The photo below shows how to connect the switch, ground wire and neutral wires.

- Connect the wires within the shed to a switch.

- Run wires from the switch to a GFCI receptacle, and from in that location to the rest of the outlets or lights in your shed.

Originally Published: Jan 14, 2021

Source: https://www.familyhandyman.com/project/electrical-wiring-how-to-run-power-anywhere/